Flexi Homes

Affordable

Economies of mass production with the advantages of flexible product design

Faster

Quick assembly on-site, only 48 hours to watertight

Flexible

Homes configured to suit the demands of individual sites and density objectives

Sustainable

More sustainable materials and methods of construction reduce environmental impact

Manufacturing efficiency and flexibility unlocks housing capacity

To achieve the goals of faster build times, repeatable quality levels and reduced costs, Innovaré Offsite has re-engineered the process of creating new housing, from design to assembly with a component-led solution, Flexihomes by Innovaré Offsite.

This innovative solution uses manufacturing disciplines and streamlined production processes to deliver greater efficiency and cost control. This is delivered through a systemised and flexible configurations to deliver economies of scale and meet individual needs. This considerable flexibility over the end product optimises land use, responds to local needs and enhances the viability of projects.

Why Component-Led?

‘Component-led’ housing is a game-changing approach. It’s perfect for any contractor or developer seeking ways to provide energy-efficient, high quality and affordable homes. The product and the process ensure that homes are delivered to a timescale and budget you can rely on.

The principal benefits are:

- Greater consistency and certainty of above-ground development costs for all systemised designs.

- Limited or no cost premium for adapting designs to suit individual site configurations

- Watertight structure achieved within 48 hours.

- Truncated build times as the structures are completed in parallel to site preparation and groundworks.

- Standardised but adaptable floor plans for a range of home types from 1 bed apartments to 4 bed houses and bungalows.

The Product

All homes feature fully fitted-out bathroom pods that are manufactured offsite and shipped as completed units to the site. The range of fittings can be adapted to suit the end-user environment and product specifications. The rest of the structure is formed from Structural Insulated Panels (SIPs). These are precision-made in Innovaré Offsite’s manufacturing facility and have a design life of 60 years.

Component-led design combines the advantages of scale with flexibility. This combination brings both cost-efficiency and cost certainty to housing development.

The Process

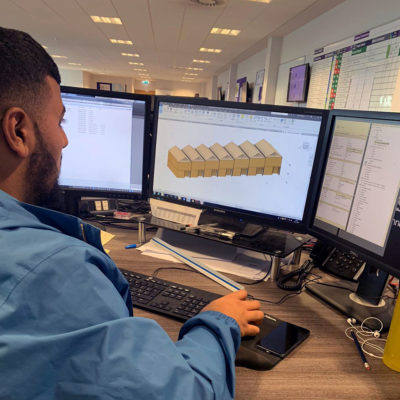

The design and manufacturing process is fully digitally-enabled. Advanced CAD technology breaks designs down into individual panels and components that are precision manufactured. The systemised designs make optimum use of the panels produced to simplify onsite assembly work and reduce waste.

Components are delivered to the site as needed where they are rapidly assembled into the dry structure ready for fit-out. Fewer defects and comprehensive ‘as-built’ documentation simplify the handover and ongoing maintenance of new homes.

Repeatable and Flexible

Flexihomes by Innovaré Offsite has the speed and repeatability of volumetric methods but without the design constraints of building from modules that have to fit on the back of a truck. While designs contain many standardised elements, each can be adapted with a very limited, or no, cost penalty to suit individual site dimensions or the required housing density or use.

FURTHER READING

Resource Centre

We have created a Resource Centre as an extension to the main website where you will find a whole host of factual and innovative information on everything relating to offsite construction. The sections we have created each deal with a specific subject and contain relevant information and stories to help you understand the benefits and differences offsite construction can deliver. We have worked with several people and organisations to create a valuable resource of information, which we constantly review and update, to respond to the changing landscape of construction and especially Modern Methods of Construction.